|

Sunrise Group Industrial Co., Ltd.

|

Flange mount type safety chucks

| Price: | 270.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Applicable for slitting machine/printing machine

2.Pretty price

Detailed Product Description

Flange mount type safety chucks

1.Easy to operation safety chuck

2.Can be customized

3.Applicable for slitting machine/printing machine

4.Pretty price

Safety chuck 35#

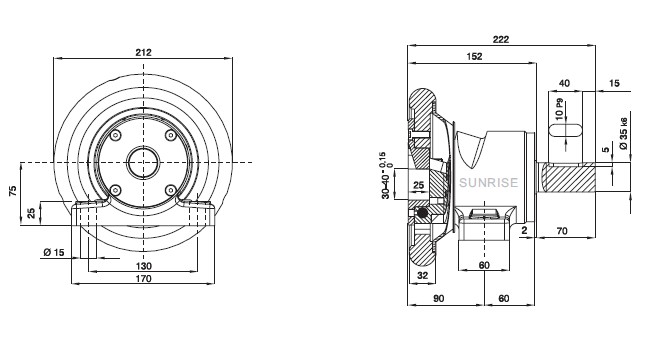

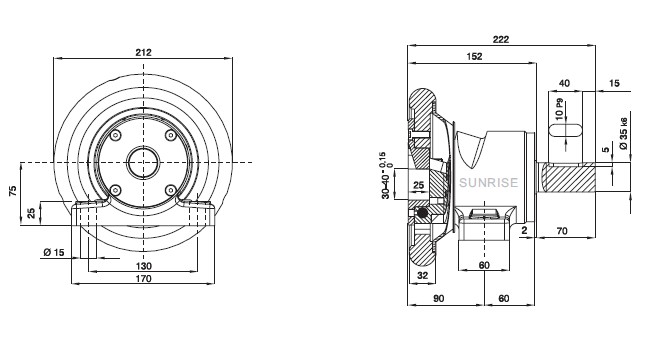

Pedestal type STO / STW

Model | STO/ STW 35# | FLO / FLW35# |

Max. loadingweight kg | 1600 | 1600 |

Max. torquekg/m (N.m) | 35(350) | 35(350) |

Square holemm | 30 / 32 / 35 / 38 / 40 | 30 / 32 / 35 / 38 / 40 |

Product weightkg | 25 | 25 |

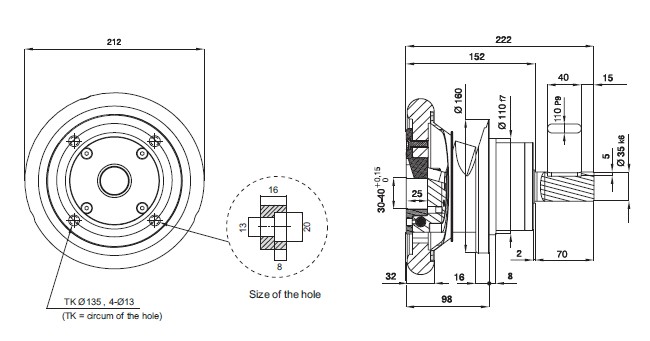

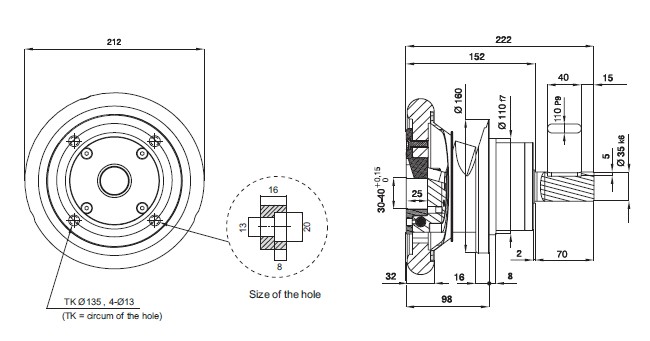

Flange type FLO / FLW

Safety Chucks do three things:

1. They provide for a quick change at the end of a production run (either winding or unwinding). Therefore, there is less down time during turn around and the more cost effective in operation.

2 . They provide a means of transmitting torque to the roll being wound / unwound. Torque in the form of a drive on the rewind end of the operation and torque from a brake on the unwind side.

3. Finally, Safety Chucks provide for concentricity between centreline, or axis, of the Safety Chuck and the center line of the Air Shaft. Less eccentricity between the Air Shaft and Safety Chuck results in less vibration and wear.

Performance and advantages: Air shaft in practical applications, it has advantages of convenient operation, quick, without damage rolls etc...

Product usage: It is widely used in printing, cutting, coating, compounding and other machineries' releasing and winding scroll.

Pedestal mount/flange mount safety chucks